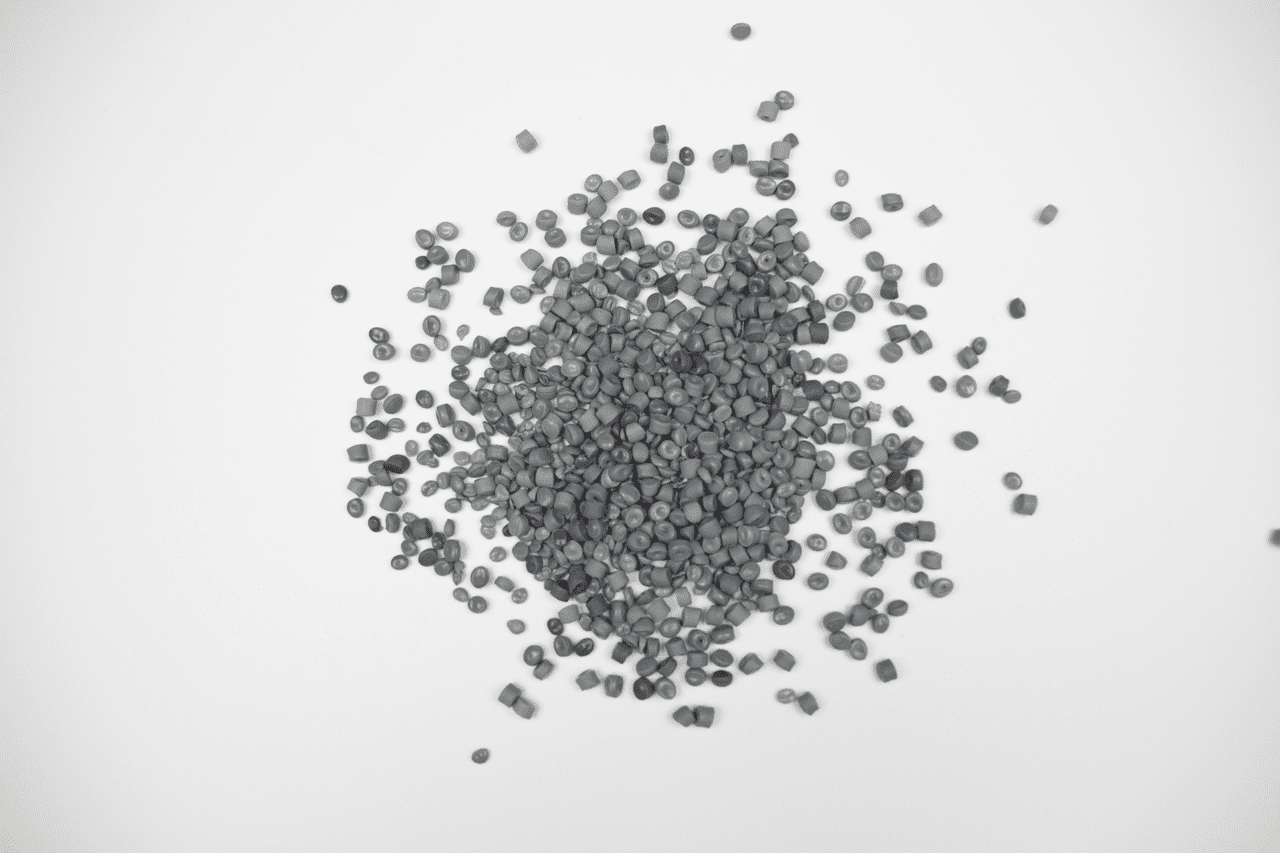

PE regranulate as an environmentally friendly alternative

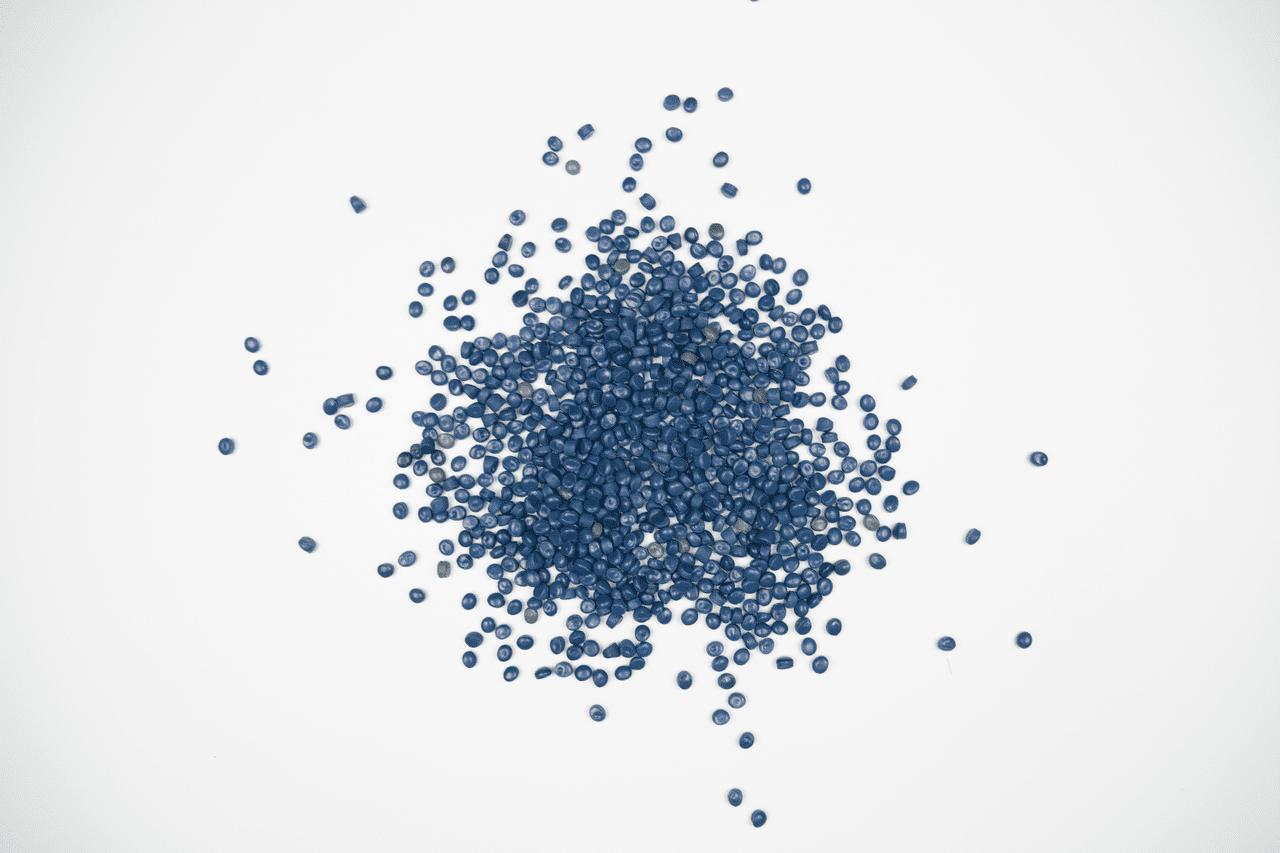

PE regranulates are regranulates made of polyethylene. Within the group of polyethylenes, a distinction is made between other types of plastic. One of these is LDPE, also known as PE-LD. LD stands for low-density and describes the lower density of the material, which is also noticeable in the high light transmission up to complete transparency.

PE regranulates are characterised in particular by their extremely high temperature resistance, toughness and elongation at break. The fact that LDPE regranulate is particularly stretchable, tasteless and odourless makes it ideal for the production of film products such as bin liners, packaging or bags.

By using PE regranulates, you make your products from 100% recycled polyethylene. This means that you can produce sustainably with high-quality PE regranulate without compromising on your quality standards.

Reasons for using PE regranulate

Even today, many applications still rely on virgin material instead of PE regranulate, such as LDPE regranulate. There are several reasons for this:

Firstly, the impression is often created that PE recycling has no price advantage compared to virgin material. But this is not the case: in the meantime, the use of regranulates is cheaper than the use of virgin material.

On the other hand, processors are concerned that process and quality problems will occur. This objection is justified, especially since PE regranulates on the market show great differences in quality and high proportions of foreign and impurity materials. For this reason, PE recycling has not been an alternative to virgin material for many plastics processors.

With the high-quality and economically interesting PE regranulate from SL Recycling GmbH, you are offered an alternative where you do not have to decide between quality and environmental protection.

Thanks to the use of state-of-the-art technology, even comparatively low-quality plastic waste from the post-consumer sector, which is available in large quantities, can be recycled and used for the production of high-quality PE regranulates that are free of foreign substances.

With the proximity to the numerous local plastics processors in the district of Vechta and the surrounding area, material cycles can be closed and plastic waste given a new lease of life.

This type of regranulate is not what you need? Click here for our PP regranulates!

The LDPE regranulate production process

PE recycling takes place in two steps:

First of all, the film waste is sorted. First, everything is ground into small pieces and roughly separated from foreign matter and dirt. Then the film waste is sorted using NIR technology. This is a process by SL Recycling GmbH in which a sensor detects the material and colour of the waste and separates it fully automatically using air.

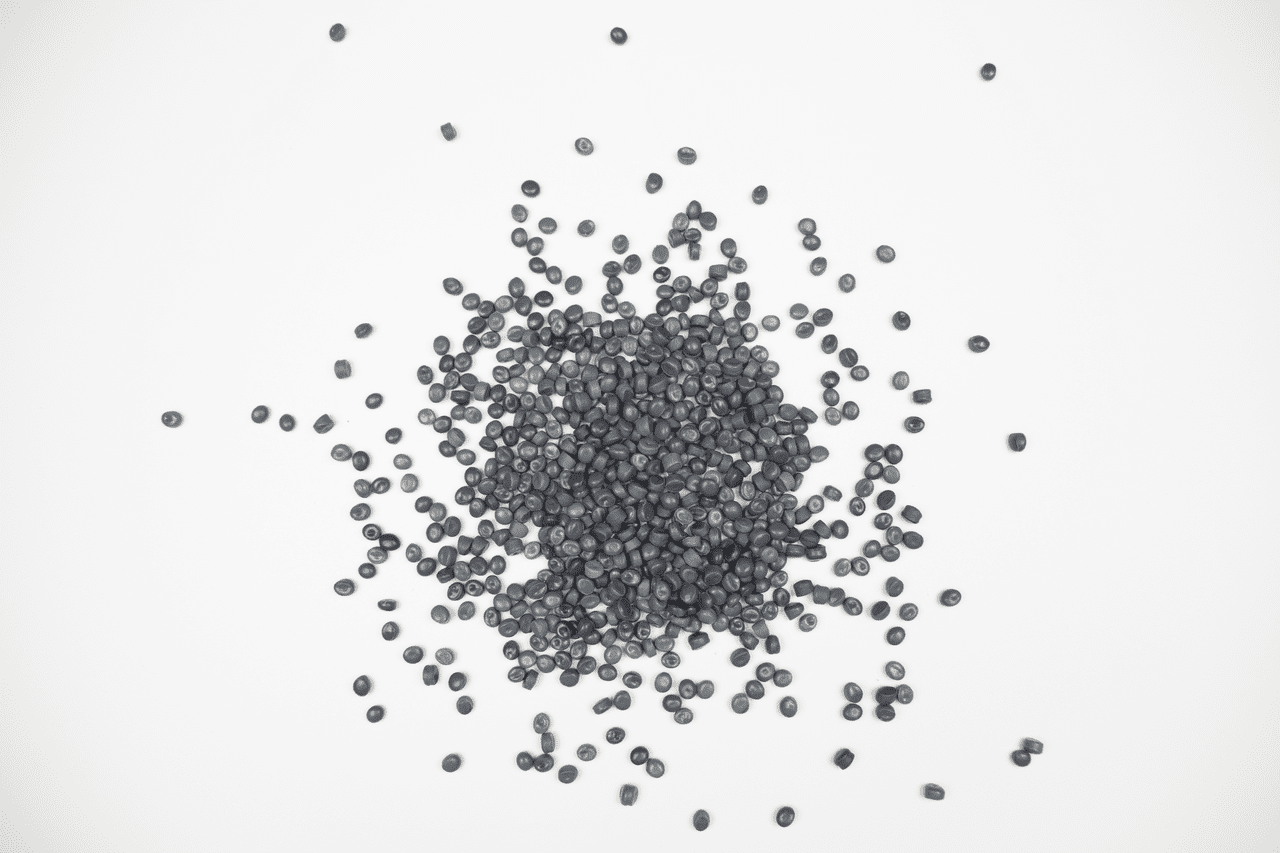

In the second step of PE recycling, extrusion or re-granulation takes place. The material is first further shredded and then enters the so-called dry cleaning process. In this process, large amounts of dirt and dust are removed from the films and then enter a bunker where the material is pre-mixed in larger quantities. It is then conveyed to the extruder, where it is melted above temperature. It is then mixed with a screw.

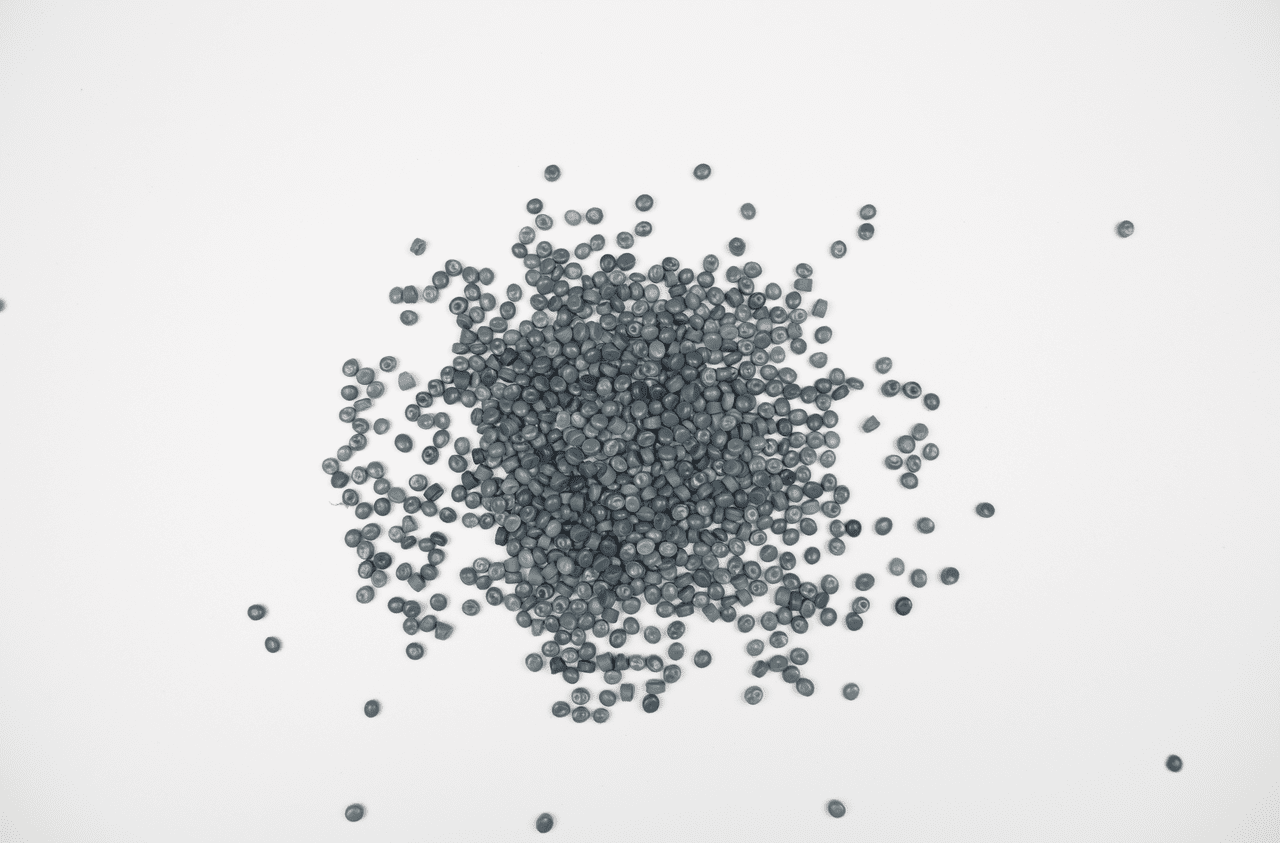

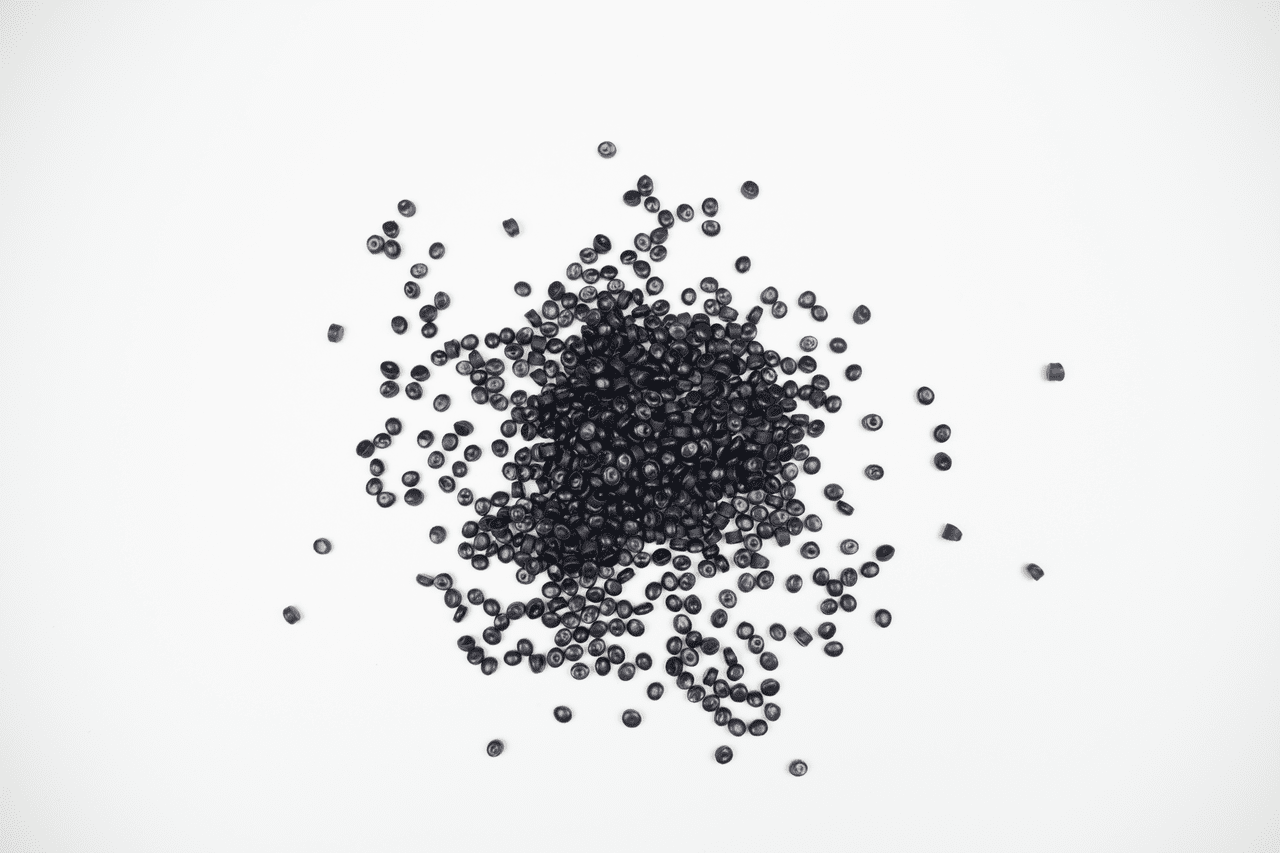

From here it goes on to filtration, where the other dirt particles are filtered out of the material. Afterwards, a kind of strand is obtained from which granulate grains are formed via a hot cut and cooling in water.

In the further course, the material is homogenised in a mixing silo in order to guarantee constant characteristic values and a uniform colouring of the PE regranulate. Finally, the PE regranulate enters a storage silo from which it can be bagged into specific packaging.

This is how PE recycling works with SL Recycling GmbH

Have we aroused your interest in a more cost-effective and environmentally friendly alternative to virgin plastic? Let us advise you comprehensively now!

As a professional and experienced PE recycling company, we will be happy to answer your questions about PE or LDPE regranulate. Whether in person on site, by video conference or classically by telephone – we will find a solution that suits you!

To ensure that we meet your requirements in the best possible way, we then compare your needs with our product range. We then exchange data by preparing a quotation for our PE and LDPE regranulates and sending you the corresponding data sheets.

In the next step, we will send you a free sample of the PE or LDPE regranulate so that you can convince yourself of the high quality of our PE recycling process.

You can decide for yourself which batch size, packaging and product labelling best suit your internal processes. Just as you are free to choose the quality documentation for your PE or LDPE regranulate.

Send us your plastic waste in a relaxed manner and get back high-quality PE or LDPE regranulate!

Would you like to learn more about us and our company? Click here for our mission!